Welcome to our Taper Calculator web page! This handy tool is designed to assist you in calculating taper length, taper per inch (TPI), and taper angle for tapered objects. Whether you’re working on machining, manufacturing, or engineering projects, our Taper Calculator simplifies the process of determining the taper dimensions with precision. Just input the major and minor diameters, as well as the taper angle, and let the calculator do the rest. Save time and ensure accuracy in your tapered component designs with our easy-to-use Taper Calculator. Start calculating tapers now and streamline your projects for optimal results!

Taper per inch (TPI): inches

Taper per foot (TPF): inches

Taper angle (θ): degrees

Taper length (L): inches

Taper ratio (1:X):

What is a Taper Calculator?

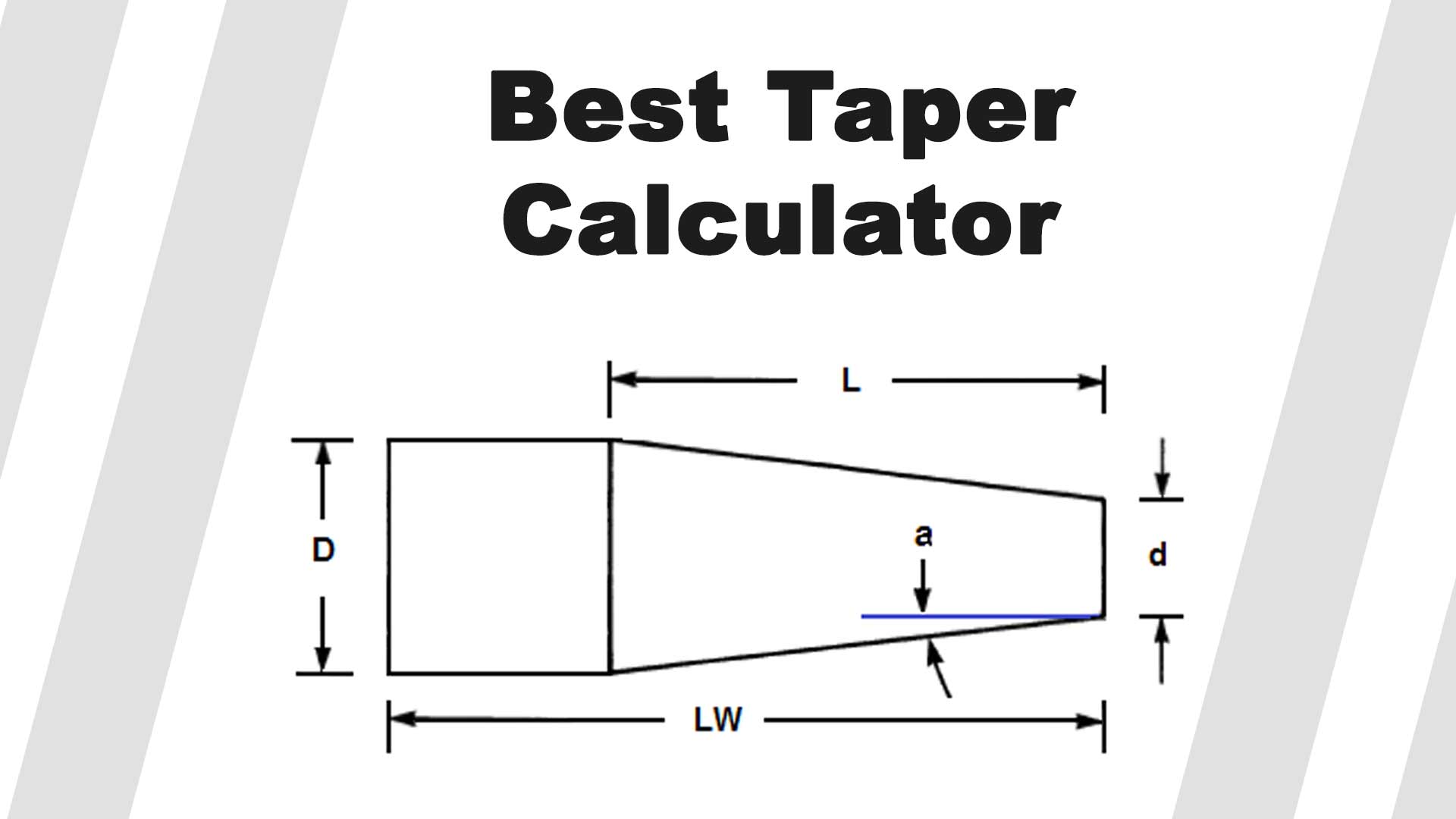

A Taper Calculator is a tool used to calculate various parameters related to tapered objects or components. Tapering refers to the gradual reduction or increase in size or dimensions of an object from one end to the other. This is commonly seen in objects such as conical shapes, shafts, pipes, or tools like reamers and drill bits.

A Taper Calculator typically takes input values such as the major diameter, minor diameter, and taper angle and provides essential measurements, including:

- Taper per inch (TPI): This represents the change in diameter per inch of length along the taper.

- Taper per foot (TPF): Similar to TPI, but expressed as the change in diameter per foot of length along the taper.

- Taper angle (θ): The angle at which the taper expands or contracts. It is typically measured in degrees.

- Taper length (L): The difference in length between the major and minor diameters.

- Taper ratio (1:X): This ratio indicates how much larger or smaller the major diameter is compared to the minor diameter.

Taper Calculators are commonly used in various industries, such as manufacturing, machining, woodworking, and metalworking. Moreover, they are valuable tools for engineers, machinists, and craftsmen to design and produce tapered components with precise dimensions and angles.

The calculator is especially useful for tasks like designing tapered shafts, ensuring proper fits for tapered joints, or understanding the characteristics of tapered tools. With the help of a Taper Calculator, accurate measurements and dimensions can be obtained, leading to better quality and more efficient tapered products.

How does this Taper Calculator work?

This Taper Calculator works by taking input values for the major diameter, minor diameter, and taper angle. Then, using mathematical formulas to calculate various parameters related to the tapered object. Let’s break down the steps of how the Taper Calculator works:

- User Input: The user enters the values for the major diameter (Dl), the minor diameter (Ds), and the taper angle (θ) into the input fields of the calculator.

- Data Validation: The calculator first checks whether the user has entered valid numbers for all the input fields. If any of the input values are invalid (e.g., non-numeric or missing), the calculator displays an alert message to the user, prompting them to enter valid numbers.

- Taper per Inch (TPI) Calculation: The calculator uses the formula TPI = 2 * tan(θ) to calculate the taper per inch. It takes the tangent of the taper angle in degrees (converted to radians) and then multiplies it by 2.

- Taper per Foot (TPF) Calculation: To calculate the taper per foot, the calculator simply multiplies the taper per inch value by 12, as there are 12 inches in a foot.

- Taper Length (L) Calculation: The taper length is calculated by subtracting the minor diameter (Ds) from the major diameter (Dl).

- Taper Ratio (1:X) Calculation: The taper ratio is calculated by taking the reciprocal of the taper per foot. So, taper ratio = 1 / TPF.

- Displaying Results: Once all the calculations are performed, the Taper Calculator displays the results on the screen. It shows the calculated values for TPI, TPF, taper angle, taper length, and taper ratio.

Using these calculations, the Taper Calculator provides valuable information to engineers, machinists, and craftsmen to design and manufacture tapered components with precise dimensions and angles.

The formula used in this Taper Calculator with the example

The Taper Calculator uses the following formulas to calculate various parameters related to the tapered object:

- Taper per Inch (TPI): Formula: TPI = 2 * tan(θ) Description: TPI represents the change in diameter per inch of length along the taper. It is calculated by taking the tangent of the taper angle (θ) in degrees and then multiplying it by 2.

- Taper per Foot (TPF): Formula: TPF = TPI * 12 Description: TPF is similar to TPI but is expressed as the change in diameter per foot of length along the taper. It is calculated by multiplying the TPI value by 12, as there are 12 inches in a foot.

- Taper Length (L): Formula: L = Dl – Ds Description: Taper length represents the difference in length between the major diameter (Dl) and the minor diameter (Ds).

- Taper Ratio (1:X): Formula: Taper Ratio = 1 / TPF Description: The taper ratio indicates how much larger or smaller the major diameter (Dl) is compared to the minor diameter (Ds). It is calculated by taking the reciprocal of the taper per foot (TPF) value.

Examples

Let’s use an example to illustrate how the Taper Calculator works:

Example: Estimate the taper length for a workpiece having major and minor diameters of 12 inches and 6 inches, respectively. The taper angle is 80.5 degrees.

Step 1:

User Input

- Major Diameter (Dl) = 12 inches

- Minor Diameter (Ds) = 6 inches

- Taper Angle (θ) = 80.5 degrees

Step 2:

TPI Calculation TPI = 2 * tan(80.5 degrees) ≈ 11.952 inches

Step 3:

TPF Calculation TPF = TPI * 12 ≈ 11.952 * 12 ≈ 143.424 inches

Step 4:

Taper Length (L) Calculation L = Dl – Ds = 12 – 6 = 6 inches

Step 5:

Taper Ratio Calculation Taper Ratio = 1 / TPF ≈ 1 / 143.424 ≈ 0.00698 (rounded to three decimal places)

Step 6:

Displaying Results

- TPI ≈ 11.952 inches

- TPF ≈ 143.424 inches

- Taper Angle (θ) = 80.5 degrees

- Taper Length (L) = 6 inches

- Taper Ratio ≈ 1:143.424 (rounded to three decimal places)

The Taper Calculator provides these results based on the input values, helping users understand the dimensions and characteristics of the tapered object and enabling them to make informed decisions in their design and manufacturing processes.

Data source, Algorithm, accuracy and performance of this Taper calculator

We created this Taper calculator based on the information from Brad Williams and Matt Jones. Moreover, we have gone through several scientific papers. Brad Williams is a mechanical engineer who has been working with taper for a long time. Moreover, Matt Jones is a mathematics professor specialising in mathematical formulas and equations. By combining the suggestions from these two guys, we created the algorithm for the taper calculator. They also validated the accuracy and performance of this calculator. We got nearly 100% accuracy on different tests.

We have also collected the strategies and knowledge for different open-source websites and scientific papers. The scientific papers include:

- The effects of taper on performance in distance runners

- A Practical Approach to the Taper

- New Guidelines for Preparation Taper

- An evaluation of factors influencing pore pressure in accretionary complexes: Implications for taper angle and wedge mechanics

- Effect of taper geometries and launch angle on evanescent wave penetration depth in optical fibers

- Effects of thread depth, taper shape, and taper length on the mechanical properties of mini-implants

- The effects of abutment taper, length and cement type on resistance to dislodgement of cement-retained, implant-supported restorations

How do you calculate the taper angle?

The taper angle is calculated using trigonometric functions, specifically the inverse tangent (arctan or tan^-1) function. The formula to calculate the taper angle (θ) is as follows:

θ = atan((Dl – Ds) / L)

Where:

- θ is the taper angle in radians

- Dl is the major diameter

- Ds is the minor diameter

- L is the taper length

If you prefer the angle in degrees instead of radians, you can convert it using the formula:

θ (degrees) = θ (radians) * (180 / π)

Where π (pi) is approximately 3.14159265359.

Let’s use an example to illustrate how to calculate the taper angle:

Example: Suppose we have a tapered object with a major diameter (Dl) of 12 inches, a minor diameter (Ds) of 6 inches, and a taper length (L) of 4 inches.

Step 1: Calculate the taper angle in radians θ = atan((12 – 6) / 4) ≈ atan(6 / 4) ≈ atan(1.5) ≈ 0.9828 radians

Step 2: Convert the taper angle to degrees θ (degrees) = 0.9828 * (180 / π) ≈ 56.309 degrees

So, the taper angle for this example is approximately 0.9828 radians or 56.309 degrees. This angle represents the inclination or slope of the taper and is used to characterize how the object’s diameter changes along its length.

What is the taper ratio in this calculator?

In the Taper Calculator, the taper ratio represents the relationship between the major diameter (Dl) and the minor diameter (Ds) of the tapered object. It is expressed as a ratio in the format “1:X”, where “X” is the factor by which the major diameter is larger or smaller than the minor diameter.

The formula to calculate the taper ratio is:

Taper Ratio = 1 / TPF

Where:

- TPF is the taper per foot, which is the change in diameter per foot of length along the taper.

The taper ratio indicates how much larger or smaller the major diameter is compared to the minor diameter. If the taper ratio is greater than 1, it means the major diameter is larger than the minor diameter, and if it is less than 1, it means the major diameter is smaller than the minor diameter.

For example: If the taper ratio is 1:12, it means that for every 12 inches of length along the taper, the major diameter is 1 inch larger than the minor diameter.

The taper ratio is a useful parameter for understanding the relative size difference between the two ends of the tapered object. It is commonly used in various industries, such as manufacturing and machining, to describe tapered components’ characteristics and ensure proper fits for tapered joints and connections.

Taper Chart

Taper Chart with Taper per Inch (TPI)

| Taper Angle (degrees) | Taper per Inch (TPI) |

| 5° | 0.087 |

| 10° | 0.176 |

| 15° | 0.268 |

| 20° | 0.364 |

| 25° | 0.466 |

| 30° | 0.577 |

| 35° | 0.700 |

| 40° | 0.839 |

| 45° | 1.000 |

Taper Chart with Taper per Foot (TPF)

| Taper Angle (degrees) | Taper per Inch (TPI) |

| 5° | 0.087 |

| 10° | 0.176 |

| 15° | 0.268 |

| 20° | 0.364 |

| 25° | 0.466 |

| 30° | 0.577 |

| 35° | 0.700 |

| 40° | 0.839 |

| 45° | 1.000 |

Tapers sizes chart

| Taper Size (Taper Number) | Taper Angle (degrees) |

|---|---|

| 1 | 1.7899 |

| 2 | 2.8611 |

| 3 | 4.5159 |

| 4 | 4.7628 |

| 5 | 5.4000 |

| 6 | 5.5312 |

| 7 | 7.1250 |

| 8 | 8.0000 |

| 9 | 9.4587 |

| 10 | 9.6000 |

| 11 | 11.0000 |

| 12 | 11.2517 |

| 13 | 12.0000 |

| 14 | 13.1579 |

| 15 | 14.4775 |

| 16 | 15.0000 |

| 17 | 16.0000 |

| 18 | 16.9442 |

| 19 | 18.7500 |

| 20 | 19.0000 |

What is the taper number?

Taper number, also known as Morse Taper number, is a numerical designation used to specify the size and type of a Morse Taper shank. Morse Taper is a type of taper commonly used in machine tool spindles, drill presses, lathes, and other machinery to secure various tools and accessories.

The Morse Taper system is based on a standardized series of tapers, each with a unique taper number. The taper number indicates the size and fit of the tapered shank and its corresponding receptacle, such as the spindle or tailstock of a machine. The higher the taper number, the larger the shank diameter, and, consequently, the larger the tool it can accommodate.

Morse Taper numbers typically range from 0 to 7, with higher numbers indicating larger tapers. The most commonly used taper numbers are Morse Taper #1, #2, #3, and #4. Tapers with higher numbers are larger and used for heavy-duty applications, while lower taper numbers are generally used for lighter-duty tasks.

Morse Taper numbers ensure compatibility and ease of use when selecting and fitting tools into the appropriate machines, making it a widely adopted system in the machining and metalworking industries.

Morse Taper number with their typical applications

Here’s a comprehensive list of Morse Taper numbers along with their typical applications:

- Morse Taper #0: Delicate instruments, small clocks, and some small machine tools.

- Morse Taper #1: Small machine tools, including drill presses, lathe centres, and small milling machines.

- Morse Taper #2: Lathe tailstocks, small to medium-sized drill presses, and milling machines.

- Morse Taper #3: Larger drill presses, milling machines, and lathes for heavy-duty applications.

- Morse Taper #4: Heavy-duty tools, large lathes, and milling machines.

- Morse Taper #5: Heavy-duty machine tools, large lathes, milling machines, industrial applications.

- Morse Taper #6: Heavy-duty machine tools, large lathes, milling machines, industrial applications.

- Morse Taper #7: Specialized industrial machinery, extremely heavy-duty applications.

Each Morse Taper number corresponds to a specific size, and tools or accessories with matching taper numbers can be easily interchanged and secured in machines with compatible tapers. This standardization allows for greater versatility and ease of use in machining and metalworking operations.